A look at the SOLGW M4-76 AR-15 and the company that makes it, Sons of Liberty Gun Works.

Like it or not, not all AR-15s are created equal.

Some rifle manufacturers are content with putting out guns that are just good enough to have the misleading “mil-spec” marketing label slapped on them. Consumers sometimes read that as some mark of quality, but the truth is that the mil-spec claim is nothing more than a flashy way of saying, “This might work with other mil-spec things.”

The reality is, few manufacturers build their M4-like carbines to a standard even remotely close to the actual military specification for the M4A1, MIL-DTL-71186B. Fewer still will take the rifle to the next level of hard-use performance.

The boys at Sons of Liberty Gun Works (SOLGW) make that list. As much as I want to gush about my personal M4-76 rifle, the story of how the Sons came to be is equally as impressive.

Humble Origins

Sons of Liberty Gun Works is the American dream. Let’s be real about it: If you reduce the company’s start to a Netflix show description, it sounds too ridiculous to be a true story.

“With only $7,000 in his pocket after selling his car, Mike partnered up with a friend in the basement of a lumber yard to take on the biggest AR-15 manufacturers in the world. His quest? To become the best rifle company. Either they sell the whole batch of 10 rifles, or it will be game over.”

Pure insanity, but it’s the truth.

Like any good story, there’s a moment that speaks to our hero and motivates them to do something epic; in this case, it was an armorer’s course taught by the late Will Larson of Semper Paratus Arms. Mike Mihalski borrowed a friend’s AR-15, enrolled in the two-day course and learned far more than he could’ve imagined. I say this with some authority, because I also took Larson’s armorer course with a borrowed rifle and can attest to it being an eye-opening experience.

Mike saw the AR-15 in a new light and decided he wanted to get into the gun business. His dream of starting a gun company—building the best AR-15s he possibly could—started floating around in his head. Talking more about it with his best friend, a Navy SEAL, he eventually was introduced to Kyle Grothues; the trio had big dreams about taking on the big names in the AR industry. Mike sold his car, netting him $7,000, and Kyle brought a little more cash to the table and some space in the family-owned lumber company his great-grandfather founded in 1933.

With limited funds and no standing purchase orders, the boys had some serious work ahead of them. The limited funds were a pretty significant hurdle initially, especially since most of the suppliers of components that Mike felt acceptable enough to put in a rifle he was building had order minimums in the hundreds. The Sons only had the cash for 10 guns worth of parts. Rather than let his standards slip, Mike hounded suppliers and willed those first 10 rifles into existence.

Some of the first 10 went to friends of Mike and Kyle, and the remaining rifles found a home with some men who know what a hard-use rifle needs to be: The Navy SEALs and Marines who bought one of the Sons’ first rifles spread the good word. It didn’t take long for other guys looking for a no-nonsense duty rifle to reach out to Sons of Liberty; the endorsement of Navy SEALs and Marines can be a powerful marketing tool.

Orders for more guns came rolling in.

Making Their Mark

You might be wondering what’s so damned special about some dudes in a lumberyard with an FFL and a few AR-15 parts. The Sons saw a gap in the market for hard-use rifles suitable for defensive or duty use that could be customized. Until now, if you wanted a hard-use rifle, the most ideal move was to buy something like a Colt 6920 and replace half the rifle to get it to where you wanted. The Sons’ crazy idea was to offer the same quality as Colt, but with the addition of allowing the end-user to configure their rifle how they wanted direct from the manufacturer.

Through continued research, daily conversations with Will Larson and their rifle rebuild program, Mike gathered data on what worked well and what didn’t. Eventually, Sons of Liberty Gun Works took what they learned and started developing parts of their very own, with the goal of building the best damn rifle in America.

At the core of their success is the quality control that goes into each and every rifle. It isn’t just grabbing parts from a bin and slapping a rifle together; each part is inspected multiple times to ensure it’s within acceptable specs. If the part isn’t up to their high standards, it isn’t used.

Their commitment to quality goes beyond just measuring parts. More durable anodizing, slightly tweaked upper receiver dimensions to remove the wobble found on almost every AR-15, and ensuring their components are made of the best materials for that particular use, take the SOLGW rifles and components to the next level.

Once you have top-tier components, the only thing holding a rifle back from being the best it possibly can be is how those parts are assembled—you can’t just slap a rifle together at your kitchen table and expect world-class performance. I was given a chance to visit the SOLGW factory, and I can’t overstate the meticulous care given to each and every stage of the build process.

Everyone knew proper torque values at the snap of a finger—and why each one was important. The tools they were using weren’t the cheapest thing they could get, and every rifle went together with the same level of attention. I was especially fascinated with their endplate staking. Mike and I see eye to eye on the importance of staking, but he took it a bit further and incorporated Forward Controls Design castle nuts that allow three places to stake rather than the two required to meet MIL-STD-DTL-71186B.

The SOLGW M4-76

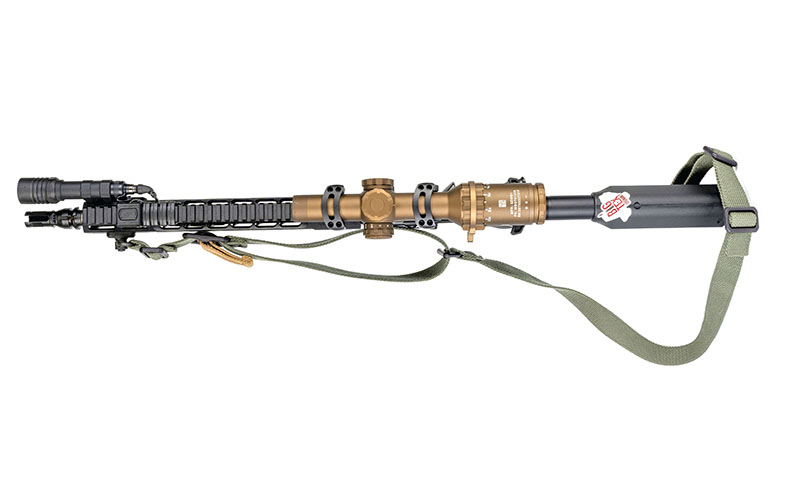

If, for some reason, I had to choose only one rifle to be my companion in some real-life version of I Am Legend, there’s only one choice: a 13.7-inch-barreled Sons of Liberty Gun Works M4-76 with their nine-position A5 buffer tube paired with a VLTOR A5 Buffer and their NOX muzzle device pinned and welded to bring it to non-NFA length. For a pure fighting rifle, I struggle to think of a more versatile option.

As you unbox your rifle, you’re met with a soft-side rifle case inside the cardboard box rather than a bunch of foam, which is fantastic for those who don’t have several rifle bags or cases already. On the outside of that soft case are three stainless steel magazines in the mag pouches, complete with SOLGW-marked floorplates and a small baggie containing a single fired case, a small bottle of lube and a Sons of Liberty Gun Works patch.

Nestled inside your soft case is the rifle. Remove the case from the box and you’ll find a lifetime warranty certificate signed by four people: the armorer who built your gun, the person who inspected the finished product and test-fired it, and the two owners of the company—stating that if you don’t start “fixing” your rifle by swapping parts around, they’ll fix the gun for life regardless of round count. Yes, that includes gas rings, barrel, bolt carrier group and springs.

I installed a SIG Sauer Tango6T 1-6x24mm scope in an old Warne mount that wasn’t doing anything in my gun room. The only other accessories I added were a Modlite OKW paired with a ModButton Lite and an Arisaka inline mount, and a Blue Force Gear Vickers sling.

During the zero process, the first several rounds I sent downrange surprised me. There was near no recoil. We can thank SOLGW for taking gas port size seriously and not building rifles to run on any random ammunition you can find. Will it run the cheap stuff? Probably. I was elated that it wasn’t heavily over-gassed like many commercial rifles.

But recoil mitigation isn’t just about gas-port sizing: The mid-length gas system, highly efficient NOX muzzle device, a SpringCo green buffer spring, nine-position A5 buffer tube and VLTOR A5-H2 buffer all play a role in keeping the rifle on target during fast strings of fire. All my shooting was faster-paced drills at 25 yards, and I haven’t seen a single malfunction.

The rifle is reasonably light, shoots soft and flat, is more than accurate at the defensive distances the average citizen would likely see if they were unfortunate enough to need to use a firearm in defense of their life, and it handles like a dream thanks to that 13.7-inch barrel with the pinned and welded NOX flash hider. Overall, this is the best AR-15 carbine I’ve had the pleasure to shoot to date.

They Do God’s Work

There just isn’t enough room here to talk about all the 2nd Amendment advocacy work Mike, Kyle and the Sons of Liberty Gun Works crew do. Never mind the massive amount of support they give law enforcement, their involvement in politics at all levels, support for gun-loving Americans or the Sons of Liberty Gun Works Carbine Series competition. They’re some of the most active and amazing people in the firearms industry.

As for my experience with the M4-76 rifle, I fully intend on purchasing a second and possibly third copy of the very same rifle for my son’s first AR-15 and maybe one for the wife … maybe.

Editor’s Note: This article originally appeared in the June 2021 issue of Gun Digest the Magazine.

More AR-15s:

NEXT STEP: Download Your Free Storm Tactical Printable Target Pack

NEXT STEP: Download Your Free Storm Tactical Printable Target Pack

62 Printable MOA Targets with DOT Drills – Rifle Range in YARDS This impressive target pack from our friends at Storm Tactical contains 62 printable targets for rifle and handgun range use. Target grids and bullseye sizes are in MOA. Ideal for long-range shooting! Get Free Targets